NEWS

Modular mounter cm402

- Categories:Industry News

- Author:Becky Su

- Origin:

- Time of issue:2022-12-07 16:03

- Views:

(Summary description)Modular mounter cm402 PanasonicCM402 Single Platform Solution: One Platform Industry* high productivity, 0.06S/CHIP (60,000cph) Flexible variety switching capability and wide range of component matching capability High production capacity. - Achieves high speed with a capacity of 60,000 CPH (system upgrade capable of reaching 66,000 CPH) - Substrate delivery time* as fast as 0.9 seconds. Flexible substrate transport, reducing lost transport time High efficiency. - CP/CPK self-check function, customers can check the accuracy of the equipment themselves during the use of the equipment - 0603 narrow pitch placement component absorption rate and product once pass through rate is the highest in the business world*, such as the current mass production of Ipod MP3 - To realize 100% automatic insertion of hand inserted components by program-controlled precision pressure insertion. For example: I/O port, shaped connector, copper column, etc. Flexible wiring options. Based on a single platform design, the CM402A/B/C models can be changed to high-speed machines/universal machines/combined machines by simply changing the head and adding a tray feeder (TRAY) - Highly efficient production with a large number of proven reliable designs that significantly reduce downtime - Fewer types of production line carriers in the world*. A total of 5 types of racks can be used for all types of tape elements. - Intelligent tape racking, automatic selection of transfer method according to components, and various other intelligent functions - Single machine* can mount up to 216 types of components - A bracket type trolley exchange connection / braiding / shelf and other filling peripheral devices to achieve non-stop material change, the actual production cranking rate of 85%-90% High placement accuracy. - High-precision placement 50μm (Cpk≧1.0) high-precision base-machine, and with high-precision calibration function and - A variety of flexible combination of ways to meet the different needs of production Perfect software system. - Simple process software, a one-time completion of the single machine optimization and production line balance optimization - LINE COMPUTER management system to monitor production management information and material usage at all times - IPC intelligent component tracking system, not only to track PCB ID and prevent material change errors, but also to monitor and provide feedback to the entire production line (including monitoring of printing presses and reflow ovens) at all times. Equipment name :CM402 Type of mounting head: High-speed general purpose No. of nozzles: 8 nozzles / head × 4 3 nozzles / head × 4 Mounting speed: 0.06 sec / Chip 0.21sec/Chip Mounting accuracy: ±0.05mm ±0.035mm Number of shelves: *Up to 216 stations (8mm double) shelves Corresponding component size. 0603C/R--L24mm×W24mm 0603C/R--L100mm×W90mm Substrate size: L50mm×W50mm~L510mm×W360mm Features. - Supports a wide range of chip component placement, from 0201 chip to 24mm X 24mm in high-speed machine mode, and from 0201 chip to 90mm X 100mm in multi-function machine mode. - High throughput of 60,000 CPH, the highest in the industry*. - Holds up to 216 types of materials (with 8mm dual shelves) - Standard trolley type one-touch changeover, belt splicing, and continuous replenishment - Board transfer time of 0.9 seconds Flexible board transfer reduces transfer time loss. - User can freely switch between A, B and C production modes on site depending on the production target. Type A High Speed Head + High Speed Head Type B Multifunctional Head + Multifunctional Head (can be equipped with pallet feeder) Type C High-speed Head + Multi-functional Head (can be equipped with pallet feeder) If you want to switch freely between high-speed and multifunctional machines on one bonder, the CM402 with its fast switching platform is the right choice for you. Its high speed mode has a capacity of 60,000 CPH and ±50μm accuracy for substrates up to 18 "x 20". Its multi-function mode also has a capacity of 17,140 CPH and ±35μm accuracy. In addition to high speed and switchability, the CM402 has several other advantages. Its user-friendly interface makes operation and programming easy and simple. It allows for fast substrate transfer and easy product changeover, minimizing production crop losses.

Modular mounter cm402

(Summary description)Modular mounter cm402

PanasonicCM402

Single Platform Solution: One Platform

Industry* high productivity, 0.06S/CHIP (60,000cph)

Flexible variety switching capability and wide range of component matching capability

High production capacity.

- Achieves high speed with a capacity of 60,000 CPH (system upgrade capable of reaching 66,000 CPH)

- Substrate delivery time* as fast as 0.9 seconds. Flexible substrate transport, reducing lost transport time

High efficiency.

- CP/CPK self-check function, customers can check the accuracy of the equipment themselves during the use of the equipment

- 0603 narrow pitch placement component absorption rate and product once pass through rate is the highest in the business world*, such as the current mass production of Ipod MP3

- To realize 100% automatic insertion of hand inserted components by program-controlled precision pressure insertion. For example: I/O port, shaped connector, copper column, etc.

Flexible wiring options.

Based on a single platform design, the CM402A/B/C models can be changed to high-speed machines/universal machines/combined machines by simply changing the head and adding a tray feeder (TRAY)

- Highly efficient production with a large number of proven reliable designs that significantly reduce downtime

- Fewer types of production line carriers in the world*. A total of 5 types of racks can be used for all types of tape elements.

- Intelligent tape racking, automatic selection of transfer method according to components, and various other intelligent functions

- Single machine* can mount up to 216 types of components

- A bracket type trolley exchange connection / braiding / shelf and other filling peripheral devices to achieve non-stop material change, the actual production cranking rate of 85%-90%

High placement accuracy.

- High-precision placement 50μm (Cpk≧1.0) high-precision base-machine, and with high-precision calibration function and

- A variety of flexible combination of ways to meet the different needs of production

Perfect software system.

- Simple process software, a one-time completion of the single machine optimization and production line balance optimization

- LINE COMPUTER management system to monitor production management information and material usage at all times

- IPC intelligent component tracking system, not only to track PCB ID and prevent material change errors, but also to monitor and provide feedback to the entire production line (including monitoring of printing presses and reflow ovens) at all times.

Equipment name :CM402

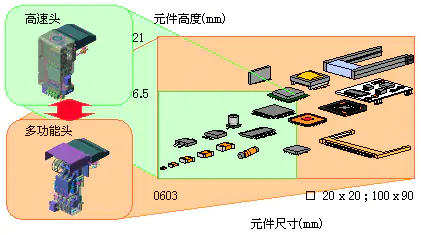

Type of mounting head: High-speed general purpose

No. of nozzles: 8 nozzles / head × 4 3 nozzles / head × 4

Mounting speed: 0.06 sec / Chip 0.21sec/Chip

Mounting accuracy: ±0.05mm ±0.035mm

Number of shelves: *Up to 216 stations (8mm double) shelves

Corresponding component size.

0603C/R--L24mm×W24mm

0603C/R--L100mm×W90mm

Substrate size: L50mm×W50mm~L510mm×W360mm

Features.

- Supports a wide range of chip component placement, from 0201 chip to 24mm X 24mm in high-speed machine mode, and from 0201 chip to 90mm X 100mm in multi-function machine mode.

- High throughput of 60,000 CPH, the highest in the industry*.

- Holds up to 216 types of materials (with 8mm dual shelves)

- Standard trolley type one-touch changeover, belt splicing, and continuous replenishment

- Board transfer time of 0.9 seconds Flexible board transfer reduces transfer time loss.

- User can freely switch between A, B and C production modes on site depending on the production target.

Type A High Speed Head + High Speed Head

Type B Multifunctional Head + Multifunctional Head (can be equipped with pallet feeder)

Type C High-speed Head + Multi-functional Head (can be equipped with pallet feeder)

If you want to switch freely between high-speed and multifunctional machines on one bonder, the CM402 with its fast switching platform is the right choice for you. Its high speed mode has a capacity of 60,000 CPH and ±50μm accuracy for substrates up to 18 "x 20". Its multi-function mode also has a capacity of 17,140 CPH and ±35μm accuracy.

In addition to high speed and switchability, the CM402 has several other advantages. Its user-friendly interface makes operation and programming easy and simple. It allows for fast substrate transfer and easy product changeover, minimizing production crop losses.

- Categories:Industry News

- Author:Becky Su

- Origin:

- Time of issue:2022-12-07 16:03

- Views:

Modular mounter cm402

PanasonicCM402

Single Platform Solution: One Platform

Industry* high productivity, 0.06S/CHIP (60,000cph)

Flexible variety switching capability and wide range of component matching capability

High production capacity.

- Achieves high speed with a capacity of 60,000 CPH (system upgrade capable of reaching 66,000 CPH)

- Substrate delivery time* as fast as 0.9 seconds. Flexible substrate transport, reducing lost transport time

High efficiency.

- CP/CPK self-check function, customers can check the accuracy of the equipment themselves during the use of the equipment

- 0603 narrow pitch placement component absorption rate and product once pass through rate is the highest in the business world*, such as the current mass production of Ipod MP3

- To realize 100% automatic insertion of hand inserted components by program-controlled precision pressure insertion. For example: I/O port, shaped connector, copper column, etc.

Flexible wiring options.

Based on a single platform design, the CM402A/B/C models can be changed to high-speed machines/universal machines/combined machines by simply changing the head and adding a tray feeder (TRAY)

- Highly efficient production with a large number of proven reliable designs that significantly reduce downtime

- Fewer types of production line carriers in the world*. A total of 5 types of racks can be used for all types of tape elements.

- Intelligent tape racking, automatic selection of transfer method according to components, and various other intelligent functions

- Single machine* can mount up to 216 types of components

- A bracket type trolley exchange connection / braiding / shelf and other filling peripheral devices to achieve non-stop material change, the actual production cranking rate of 85%-90%

High placement accuracy.

- High-precision placement 50μm (Cpk≧1.0) high-precision base-machine, and with high-precision calibration function and

- A variety of flexible combination of ways to meet the different needs of production

Perfect software system.

- Simple process software, a one-time completion of the single machine optimization and production line balance optimization

- LINE COMPUTER management system to monitor production management information and material usage at all times

- IPC intelligent component tracking system, not only to track PCB ID and prevent material change errors, but also to monitor and provide feedback to the entire production line (including monitoring of printing presses and reflow ovens) at all times.

Equipment name :CM402

Type of mounting head: High-speed general purpose

No. of nozzles: 8 nozzles / head × 4 3 nozzles / head × 4

Mounting speed: 0.06 sec / Chip 0.21sec/Chip

Mounting accuracy: ±0.05mm ±0.035mm

Number of shelves: *Up to 216 stations (8mm double) shelves

Corresponding component size.

0603C/R--L24mm×W24mm

0603C/R--L100mm×W90mm

Substrate size: L50mm×W50mm~L510mm×W360mm

Features.

- Supports a wide range of chip component placement, from 0201 chip to 24mm X 24mm in high-speed machine mode, and from 0201 chip to 90mm X 100mm in multi-function machine mode.

- High throughput of 60,000 CPH, the highest in the industry*.

- Holds up to 216 types of materials (with 8mm dual shelves)

- Standard trolley type one-touch changeover, belt splicing, and continuous replenishment

- Board transfer time of 0.9 seconds Flexible board transfer reduces transfer time loss.

- User can freely switch between A, B and C production modes on site depending on the production target.

Type A High Speed Head + High Speed Head

Type B Multifunctional Head + Multifunctional Head (can be equipped with pallet feeder)

Type C High-speed Head + Multi-functional Head (can be equipped with pallet feeder)

If you want to switch freely between high-speed and multifunctional machines on one bonder, the CM402 with its fast switching platform is the right choice for you. Its high speed mode has a capacity of 60,000 CPH and ±50μm accuracy for substrates up to 18 "x 20". Its multi-function mode also has a capacity of 17,140 CPH and ±35μm accuracy.

In addition to high speed and switchability, the CM402 has several other advantages. Its user-friendly interface makes operation and programming easy and simple. It allows for fast substrate transfer and easy product changeover, minimizing production crop losses.

Related News

CONTACT US

Hotline:(0086)755-27801389

Mobile: (0086)15323874439

Sale No.1: becky@hysmt.cn

Sale No.2: fhysmt@hysmt.cn

Sale No.3: zksale@hysmt.cn

Sale No.4: sale@hysmt.cn

Sale No.5: elsey@hysmt.cn

GIVE ME A MESSAGE

Copyright: ZK Electronic Technology Co., Ltd 粤ICP备11054297号 Powered by www.300.cn