NEWS

Routine spot check and maintenance of Yamaha SMT feeder

- Categories:Industry News

- Author:Becky Su

- Origin:

- Time of issue:2022-11-30 11:08

- Views:

(Summary description)Routine spot check and maintenance of Yamaha SMT feeder Purpose: In order to use the belt feeder for a long time, it must be checked and maintained regularly. 1 Daily spot check Before using the belt feeder, please check the following items. Routine Check Items: Symptom Countermeasure Whether the fixing rod is loose Please refer to the maintenance manual Whether the material belt guide rail is loose Refer to Cleaning of Material Belt Guideway Whether the screws are loose Please tighten the screws Whether there are deformed and damaged elements Repair, replace Whether any components are missing Repair, replace 2 Cleaning of belt guide rail If garbage such as electronic components falls into the gap between the material belt guide rail and the plate, it will cause the material belt guide rail to become loose, the element conveying port will be deformed, and the element adsorption position will shift. In case of similar phenomenon, please follow the following steps to clean. Step 1 Remove the strip guide rail. Please loosen the screw fixing the upper belt guide rail shaft and remove the belt guide rail and guide rail shaft. Please use a screwdriver to turn the material belt guide rail shaft to facilitate disassembly. Remove the tape guide rail (Fig.) Step 2. Please use a brush to clean up the garbage between the material belt guide rail and the plate. Cleaning material tape guide rail (Fig.) Step 3 Confirm the operation status of the component transmission port. Confirm whether the component transmission port is operating correctly. In case of being clamped or sluggish, please replace the new belt guide rail in time. Confirm operation status (Fig.) Step 4 Install the loading belt guide rail. Install the strip guide rail and guide shaft on the plate in reverse order. Please turn the guide rail shaft 180 degrees anticlockwise with a slotted screwdriver Stretch. Keep this state and tighten the fixing screws of the strip guide rail shaft. Then, please confirm that there is no gap between the strip guide rail and the plate. Install the loading tape guide rail (Fig.) Yamaha bonder feeder routine inspection and maintenance is introduced. This article is a Yamaha bonder feeder CL model 8x4mm feeder to do the example, need Yamaha bonder feeder friends can contact me:. Yamaha chip machine pneumatic feeder,yamaha cl model feeder Yamaha chip machine YV100 series YG series pneumatic feeder YAMAHA 8MM FEEDER Yamaha chip machine YV100 series YG series pneumatic feeder YAMAHA 12MM FEEDER Yamaha Bonder YV100 Series YG Series Pneumatic Fiducial YAMAHA 16MM FEEDER Yamaha Bonder YV100 Series YG Series Pneumatic Fiducial YAMAHA 24MM FEEDER Yamaha Chip Machine YV100 Series YG Series Pneumatic Fiducial YAMAHA 32MM FEEDER Yamaha Chip Machine YV100 Series YG Series Pneumatic Fiducial YAMAHA 44MM FEEDER Yamaha YV100 series YG series pneumatic flyer YAMAHA 56MM FEEDER Yamaha CL model 8*2mm pneumatic flyer, applicable models: YAMAHA YVL88II YV100II YVL112-2; YV88X YV88XG YV100X YV100Xe YV100Xg YV100XP YG100A YG100B YG200 YG300 models; Yamaha CL model 8*4mm pneumatic flyer for YAMAHA YVL88II YV100II YVL112-2; YV88X YV88XG YV100X YV100Xe YV100Xg YV100XP YG100A YG100B YG200 YG300 models; Yamaha CL model 12mm pneumatic flyer for YAMAHA YVL88II YV100II YVL112-2; YV88X YV88XG YV100X YV100Xe YV100Xg YV100XP YG100A YG100B YG200 YG300 models; YAMAHA CL model 16mm pneumatic flyer for YAMAHA YAMAHA CL model 24mm pneumatic flyer for YAMAHA YAMAHA CL Model 32mm Pneumatic Fiducial, for YAMAHA YAMAHA CL model 44mm pneumatic flybar, applicable models: YAMAHA YAMAHA CL model 56mm pneumatic flyer, applicable models: YAMAHA Translated with www.DeepL.com/Translator (free version)

Routine spot check and maintenance of Yamaha SMT feeder

(Summary description)Routine spot check and maintenance of Yamaha SMT feeder

Purpose: In order to use the belt feeder for a long time, it must be checked and maintained regularly.

1 Daily spot check

Before using the belt feeder, please check the following items.

Routine Check Items:

Symptom

Countermeasure

Whether the fixing rod is loose

Please refer to the maintenance manual

Whether the material belt guide rail is loose

Refer to Cleaning of Material Belt Guideway

Whether the screws are loose

Please tighten the screws

Whether there are deformed and damaged elements

Repair, replace

Whether any components are missing

Repair, replace

2 Cleaning of belt guide rail

If garbage such as electronic components falls into the gap between the material belt guide rail and the plate, it will cause the material belt guide rail to become loose, the element conveying port will be deformed, and the element adsorption position will shift. In case of similar phenomenon, please follow the following steps to clean.

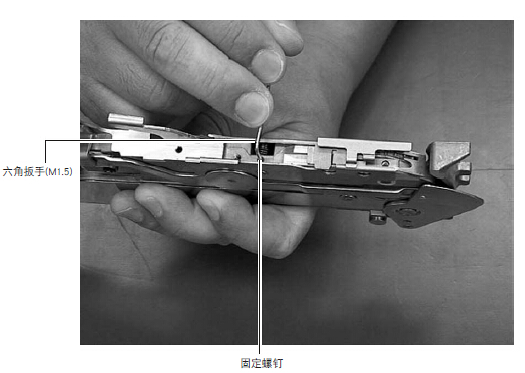

Step 1 Remove the strip guide rail.

Please loosen the screw fixing the upper belt guide rail shaft and remove the belt guide rail and guide rail shaft. Please use a screwdriver to turn the material belt guide rail shaft to facilitate disassembly.

Remove the tape guide rail (Fig.)

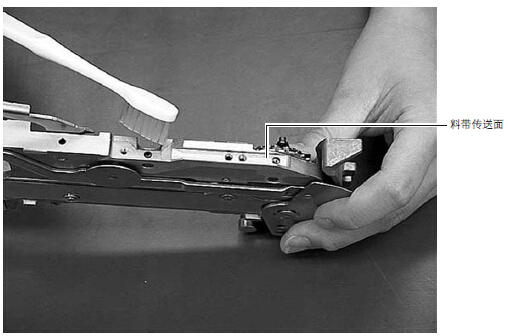

Step 2.

Please use a brush to clean up the garbage between the material belt guide rail and the plate.

Cleaning material tape guide rail (Fig.)

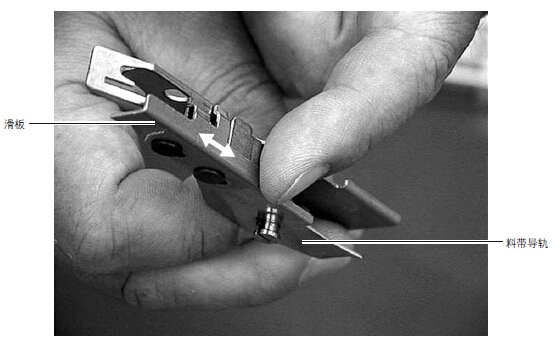

Step 3 Confirm the operation status of the component transmission port.

Confirm whether the component transmission port is operating correctly. In case of being clamped or sluggish, please replace the new belt guide rail in time.

Confirm operation status (Fig.)

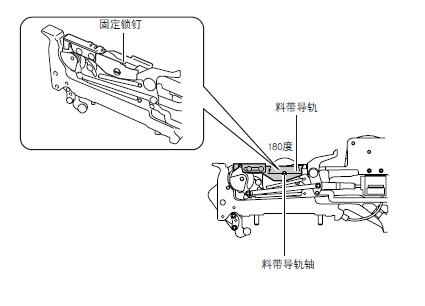

Step 4 Install the loading belt guide rail.

Install the strip guide rail and guide shaft on the plate in reverse order. Please turn the guide rail shaft 180 degrees anticlockwise with a slotted screwdriver

Stretch. Keep this state and tighten the fixing screws of the strip guide rail shaft. Then, please confirm that there is no gap between the strip guide rail and the plate.

Install the loading tape guide rail (Fig.)

Yamaha bonder feeder routine inspection and maintenance is introduced.

This article is a Yamaha bonder feeder CL model 8x4mm feeder to do the example, need Yamaha bonder feeder friends can contact me:.

Yamaha chip machine pneumatic feeder,yamaha cl model feeder

Yamaha chip machine YV100 series YG series pneumatic feeder YAMAHA 8MM FEEDER

Yamaha chip machine YV100 series YG series pneumatic feeder YAMAHA 12MM FEEDER

Yamaha Bonder YV100 Series YG Series Pneumatic Fiducial YAMAHA 16MM FEEDER

Yamaha Bonder YV100 Series YG Series Pneumatic Fiducial YAMAHA 24MM FEEDER

Yamaha Chip Machine YV100 Series YG Series Pneumatic Fiducial YAMAHA 32MM FEEDER

Yamaha Chip Machine YV100 Series YG Series Pneumatic Fiducial YAMAHA 44MM FEEDER

Yamaha YV100 series YG series pneumatic flyer YAMAHA 56MM FEEDER

Yamaha CL model 8*2mm pneumatic flyer, applicable models: YAMAHA YVL88II YV100II YVL112-2; YV88X YV88XG YV100X YV100Xe YV100Xg YV100XP YG100A YG100B YG200 YG300 models;

Yamaha CL model 8*4mm pneumatic flyer for YAMAHA YVL88II YV100II YVL112-2; YV88X YV88XG YV100X YV100Xe YV100Xg YV100XP YG100A YG100B YG200 YG300 models;

Yamaha CL model 12mm pneumatic flyer for YAMAHA YVL88II YV100II YVL112-2; YV88X YV88XG YV100X YV100Xe YV100Xg YV100XP YG100A YG100B YG200 YG300 models;

YAMAHA CL model 16mm pneumatic flyer for YAMAHA YAMAHA CL model 24mm pneumatic flyer for YAMAHA YAMAHA CL Model 32mm Pneumatic Fiducial, for YAMAHA YAMAHA CL model 44mm pneumatic flybar, applicable models: YAMAHA YAMAHA CL model 56mm pneumatic flyer, applicable models: YAMAHA

Translated with www.DeepL.com/Translator (free version)

- Categories:Industry News

- Author:Becky Su

- Origin:

- Time of issue:2022-11-30 11:08

- Views:

Routine spot check and maintenance of Yamaha SMT feeder

Purpose: In order to use the belt feeder for a long time, it must be checked and maintained regularly.

1 Daily spot check

Before using the belt feeder, please check the following items.

Routine Check Items:

| Symptom | Countermeasure |

| Whether the fixing rod is loose | Please refer to the maintenance manual |

| Whether the material belt guide rail is loose | Refer to Cleaning of Material Belt Guideway |

| Whether the screws are loose | Please tighten the screws |

| Whether there are deformed and damaged elements | Repair, replace |

| Whether any components are missing | Repair, replace |

2 Cleaning of belt guide rail

If garbage such as electronic components falls into the gap between the material belt guide rail and the plate, it will cause the material belt guide rail to become loose, the element conveying port will be deformed, and the element adsorption position will shift. In case of similar phenomenon, please follow the following steps to clean.

Step 1 Remove the strip guide rail.

Please loosen the screw fixing the upper belt guide rail shaft and remove the belt guide rail and guide rail shaft. Please use a screwdriver to turn the material belt guide rail shaft to facilitate disassembly.

Remove the tape guide rail (Fig.)

Step 2.

Please use a brush to clean up the garbage between the material belt guide rail and the plate.

Cleaning material tape guide rail (Fig.)

Step 3 Confirm the operation status of the component transmission port.

Confirm whether the component transmission port is operating correctly. In case of being clamped or sluggish, please replace the new belt guide rail in time.

Confirm operation status (Fig.)

Step 4 Install the loading belt guide rail.

Install the strip guide rail and guide shaft on the plate in reverse order. Please turn the guide rail shaft 180 degrees anticlockwise with a slotted screwdriver

Stretch. Keep this state and tighten the fixing screws of the strip guide rail shaft. Then, please confirm that there is no gap between the strip guide rail and the plate.

Install the loading tape guide rail (Fig.)

Yamaha bonder feeder routine inspection and maintenance is introduced.

This article is a Yamaha bonder feeder CL model 8x4mm feeder to do the example, need Yamaha bonder feeder friends can contact me:becky@hysmt.cn.

Yamaha chip machine pneumatic feeder,yamaha cl model feeder

Yamaha chip machine YV100 series YG series pneumatic feeder YAMAHA 8MM FEEDER

Yamaha chip machine YV100 series YG series pneumatic feeder YAMAHA 12MM FEEDER

Yamaha Bonder YV100 Series YG Series Pneumatic Fiducial YAMAHA 16MM FEEDER

Yamaha Bonder YV100 Series YG Series Pneumatic Fiducial YAMAHA 24MM FEEDER

Yamaha Chip Machine YV100 Series YG Series Pneumatic Fiducial YAMAHA 32MM FEEDER

Yamaha Chip Machine YV100 Series YG Series Pneumatic Fiducial YAMAHA 44MM FEEDER

Yamaha YV100 series YG series pneumatic flyer YAMAHA 56MM FEEDER

Yamaha CL model 8*2mm pneumatic flyer, applicable models: YAMAHA YVL88II YV100II YVL112-2; YV88X YV88XG YV100X YV100Xe YV100Xg YV100XP YG100A YG100B YG200 YG300 models;

Yamaha CL model 8*4mm pneumatic flyer for YAMAHA YVL88II YV100II YVL112-2; YV88X YV88XG YV100X YV100Xe YV100Xg YV100XP YG100A YG100B YG200 YG300 models;

Yamaha CL model 12mm pneumatic flyer for YAMAHA YVL88II YV100II YVL112-2; YV88X YV88XG YV100X YV100Xe YV100Xg YV100XP YG100A YG100B YG200 YG300 models;

YAMAHA CL model 16mm pneumatic flyer for YAMAHA YAMAHA CL model 24mm pneumatic flyer for YAMAHA YAMAHA CL Model 32mm Pneumatic Fiducial, for YAMAHA YAMAHA CL model 44mm pneumatic flybar, applicable models: YAMAHA YAMAHA CL model 56mm pneumatic flyer, applicable models: YAMAHA

Translated with www.DeepL.com/Translator (free version)

Related News

CONTACT US

Hotline:(0086)755-27801389

Mobile: (0086)15323874439

Sale No.1: becky@hysmt.cn

Sale No.2: fhysmt@hysmt.cn

Sale No.3: zksale@hysmt.cn

Sale No.4: sale@hysmt.cn

Sale No.5: elsey@hysmt.cn

GIVE ME A MESSAGE

Copyright: ZK Electronic Technology Co., Ltd 粤ICP备11054297号 Powered by www.300.cn