Welcome to ZK Electronic

Product Series

Feeders/feeder parts, nozzles, filters, lasers, servo motors, drivers, controller boards, solenoid valves, cylinders, ball screws, belts, o-rings, sensors, splice tapes/tools, clean paper rolls; clips, rubber pads, pins, guides, blades, cutters, clamps, squeegees, holders; resistors, capacitors, diodes, inductors, beads, transformers, transistors, fuse, relays, connectors, modules, processors, microcontrollers, logic chips, power chips, memory, amplifiers/linear Devices, ICs etc.

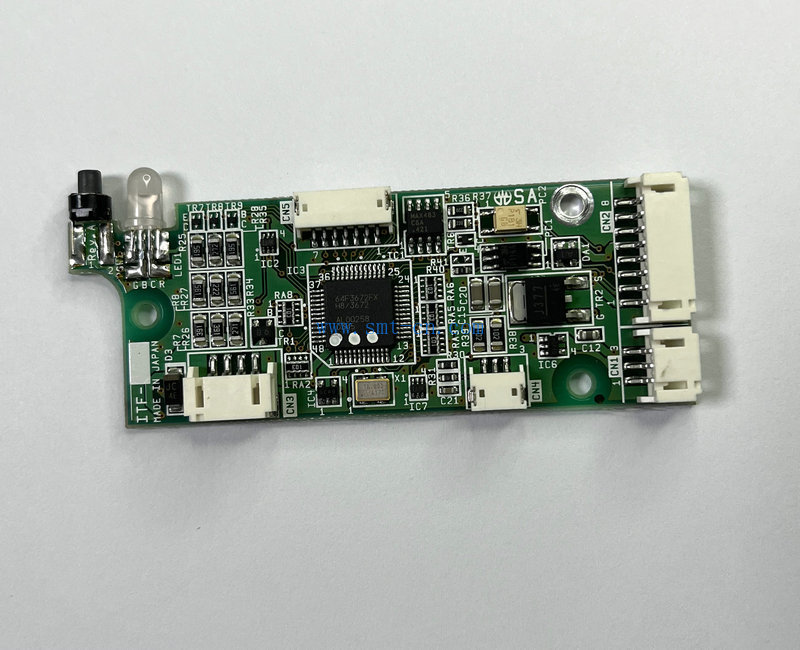

i-PULSE F2-84 feeder board LG4-M1AH1-004

i-PULSE F2-16 feeder board LG4-M1AH1-002

ZS 32MM feeder KLJ-MC545-00 Lever, Tape guide F

YAMAHA electric feeder Wave Washer KLJ-MC1F2-00

ZS 8mm feeder KLJ-MC163-00 Cover , Tail

SS 12MM feeder KHJ-MC247-01 Spring , Tape Guide F

ABOUT US

ZK Electronic Technology Co.,Limited

headquarters are located in Shenzhen, China, which is 20 minutes to Shenzhen Airport. ZK was established in 2005, we have two categories:

SMT(Surface-mount technology): highly professional in Surface-Mount Technology area and supports most major brands of electronic assembly equipment with a large selections of original/compatible SMT spare parts, Automatic Insert parts, Printer parts, such as Hanwha(Samsung), Juki, Fuji, Yamaha, Universal, Panasonic(KME), ASM/SIPLACE(SIEMENS), Sony, Sanyo, Hitachi, Assembleon(Phillips), TDK, DEK, GKG, MPM, EKRA,DSP etc. on a quotation basis.

Company Establishment

Engineers Support

Monthly Sales

Success Case

MAIN BUSINESS

1. New/Used SMT lines 2. Chip Mounter/Automatic Insert/Printer parts 3. Electronic components

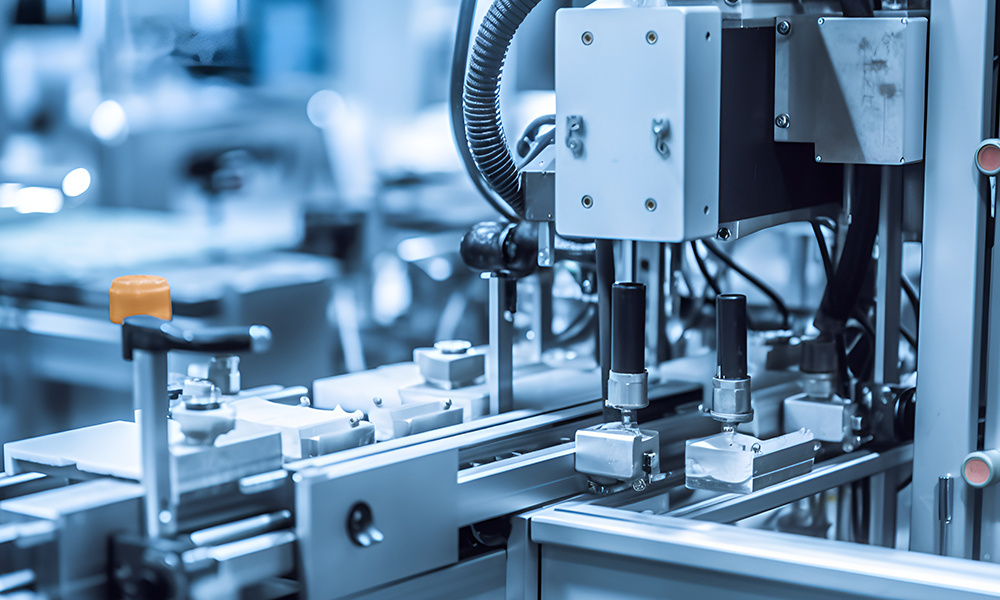

New/Used SMT lines

We Buy, Sell and Trade SMT new & used lines, specifically JUKI, Hanwha(Samsung), Yamaha, Panasonic, FUJI Pick & placement Machines. All equipment leaving our facilities are guaranteed to be fully functional, with no missing parts and in normal working condition.

Chip Mounter/Automatic Insert/Printer parts

We have good source and large ready stock for major brands of Chip mounter/Automatic Insert/Printer parts. Such as feeders/feeder parts, nozzles, filters, lasers, servo motors, drivers, controller boards, solenoid valves, ball screws, belts, sensors, splice tapes/tools, clean paper rolls, clips, pins, guides, blades, cutters, clamps, squeegees etc.

Electronic components

With the mainstream market certifications of CCC, CQC, CE, ROHS, FCC, PSE, UL, etc., ZK products are safe, reliable and quality guaranteed. The electronic components such as resistors, capacitors, diodes, inductors, beads, transformers, transistors, fuse, relays, connectors, modules, processors, microcontrollers, logic chips, power chips, memory, amplifiers/linear Devices, ICs etc.

COOPERATIVE CLIENTS

ZK Electronic Technology Co.,Limited provide Sales, Maintenance & Repair Service of SMT PCB Assembly Equipment, SMT Pick & Place Machines, Printer parts, Automatic Insertion parts, Electronic components for international famous brands.

News

Enterprise Spirit: Credible, Efficient, Dedicated, Pragmatic

Professional SMT Machine Repair & Parts Supply

2026-02-02

FUJI NXT Genuine Brand-New 3rd-Generation Calibrated Nozzle Original Fuji SMT Nozzles

2025-12-08

A well-maintained older model SM471 from overseas is available for sale

2025-12-05

Online Message

The company adheres to the principles of "integrity, efficiency, professionalism, and pragmatism" and is dedicated to providing thoughtful and complete technical and after-sales services as well as first-hand supply for domestic and foreign electronic manufacturers and customers