NEWS

Hanwha mounter DECAN S2,Hanwha high speed mounter magnetic levitation mounter introduction

- Categories:Industry News

- Author:Becky Su

- Origin:

- Time of issue:2022-12-02 11:40

- Views:

(Summary description)Hanwha mounter DECAN S2,Hanwha high speed mounter magnetic levitation mounter introduction Better area capacity than competitor's class equipment, * Optimized high-speed placement of small components One, Hanwha mounter DECAN S2 advantage: High Performance - 2 Gantry, Flying Vision Head - 92,000 CPH(Optimum, HS10 Head) High Reliability - Applicable Linear Motor, high precision, low noise - Accuracy ±28um@ Cpk≥1.0(03015) Flexible Production - Modular Conveyor System - PCB mountable 740mmx460mm Easy Operation - Can be mixed with pneumatic/electric feeders - Support smart Feeder Two, Hanwha mounter DECAN S2 features. Improve the actual production capacity 1 Improve Flying Vision Enhance LED quality at each Head position to reduce lighting deviation - Improve the visual recognition difference between Heads Improve coaxial lighting Contrast - **Ghost caused by coaxial lighting, improve component recognition rate 2 Improve S/W : Increase placement speed (80,000 CPH->92,000 CPH) Reduce Cycle time - Local reference points are assigned according to the number of placements in the relevant Cycle (5ms↓) Change of Z-Axis Inposition Count (51um->66um) - Minimize the deviation* of placement height when placing High precision placement Achieves Placement Accuracy ±28? (03015) Improved visual recognition and placement accuracy of 03015 components - By reducing FOV (24->20.5mm) Increase the number of Pixel per unit (6.5 -> 7.6) Improve X-axis position precision (resolution: 3um->2um) - Change X-Ball screw configuration (Pitch: 30mm -> 20mm) - Ease load rate Change motor configuration Improvement of Y-axis position precision(Resolution: 3um ->2um) - Change of linear motor parameters (3um ->2um) Provide a wide variety of PCB Flow Supports Modular Conveyor System that can be changed in the field to produce a wide variety of species IN/ OUT Conveyor Module can be changed quickly in the field (Shuttle method? Dual method) Work time required to change modules (mechanical and H/W for example): ~2 hours or less Range of attachable components (as shown) Hanwha mounter DECAN S2 1 Enhanced ease of equipment software management 2 Optimized software installed in the machine enables simple program creation/editing 3 Large LCD screen provides a variety of work information 4 Highly convenient, high-precision electric feeder 5 Calibration Free & Maintenance Free Electric Feeder 6 Single feeder with Reel Bank structure improves work convenience 7 Automatic alignment of component pick-up positions between feeders increases actual productivity 8 Automated feeder to reduce workload by half (SMART FEEDER) 9 The industry's first automatic feeding and receiving function The manual feeder preparation and splicing operation has been changed to an automatic method, which significantly reduces the operating time and achieves zero consumption of splicing consumables. Three, Hanwha mounter DECAN S2 model information: 1 Speed: 92000CPH 2 Accuracy: CHIP 28um(03015),IC 25um 3 Attachable components (mm): Chip 03015 ~5 axes: 12-h10 10 axes: 6-h10 4 Number of axes: 10 x 2 Head 5 Fly Camera FOV:20.5mm 6 PCB size:50 x 40 ~ 510 x 460mm Max. 740 x 460 mm (1,200 x 460 mm) 7 Feeding station:120ea 8 Machine weight:1,800kg 9 Machine size(mm):1,430(L) x 1,740(D) x 1,485(H) 10 Power supply: 3 phase AC 200/208/220/240/380/415V ±10%. 50/60Hz;Max. 5.0 Kva DECAN S2 Advanced Chip shooter 1 Speed : 92,000 CPH (Optimum) 2 Structure : 2 Gantry x 10 Spindles/Head 3 Accuracy : ±28μm Cpk≥1.0 (03015 Chip) ±25μm Cpk≥1.0 (IC) 4 Parts Size : 03015~□55mm (H15mm) 5 PCB Size : L510xW460mm (Standard) L1,200xW460mm (Option) 6 Wide Part Handling Capability 7 Various PCB Transfer Systems 8 Verified Production History Management Solution 9 High Speed Placement

Hanwha mounter DECAN S2,Hanwha high speed mounter magnetic levitation mounter introduction

(Summary description)Hanwha mounter DECAN S2,Hanwha high speed mounter magnetic levitation mounter introduction

Better area capacity than competitor's class equipment, * Optimized high-speed placement of small components

One, Hanwha mounter DECAN S2 advantage:

High Performance

- 2 Gantry, Flying Vision Head

- 92,000 CPH(Optimum, HS10 Head)

High Reliability

- Applicable Linear Motor, high precision, low noise

- Accuracy ±28um@ Cpk≥1.0(03015)

Flexible Production

- Modular Conveyor System

- PCB mountable 740mmx460mm

Easy Operation

- Can be mixed with pneumatic/electric feeders

- Support smart Feeder

Two, Hanwha mounter DECAN S2 features.

Improve the actual production capacity

1 Improve Flying Vision

Enhance LED quality at each Head position to reduce lighting deviation

- Improve the visual recognition difference between Heads

Improve coaxial lighting Contrast

- **Ghost caused by coaxial lighting, improve component recognition rate

2 Improve S/W : Increase placement speed (80,000 CPH->92,000 CPH)

Reduce Cycle time

- Local reference points are assigned according to the number of placements in the relevant Cycle (5ms↓)

Change of Z-Axis Inposition Count (51um->66um)

- Minimize the deviation* of placement height when placing

High precision placement

Achieves Placement Accuracy ±28? (03015)

Improved visual recognition and placement accuracy of 03015 components

- By reducing FOV (24->20.5mm)

Increase the number of Pixel per unit (6.5 -> 7.6)

Improve X-axis position precision (resolution: 3um->2um)

- Change X-Ball screw configuration (Pitch: 30mm -> 20mm)

- Ease load rate Change motor configuration

Improvement of Y-axis position precision(Resolution: 3um ->2um)

- Change of linear motor parameters (3um ->2um)

Provide a wide variety of PCB Flow

Supports Modular Conveyor System that can be changed in the field to produce a wide variety of species

IN/ OUT Conveyor Module can be changed quickly in the field (Shuttle method? Dual method)

Work time required to change modules (mechanical and H/W for example): ~2 hours or less

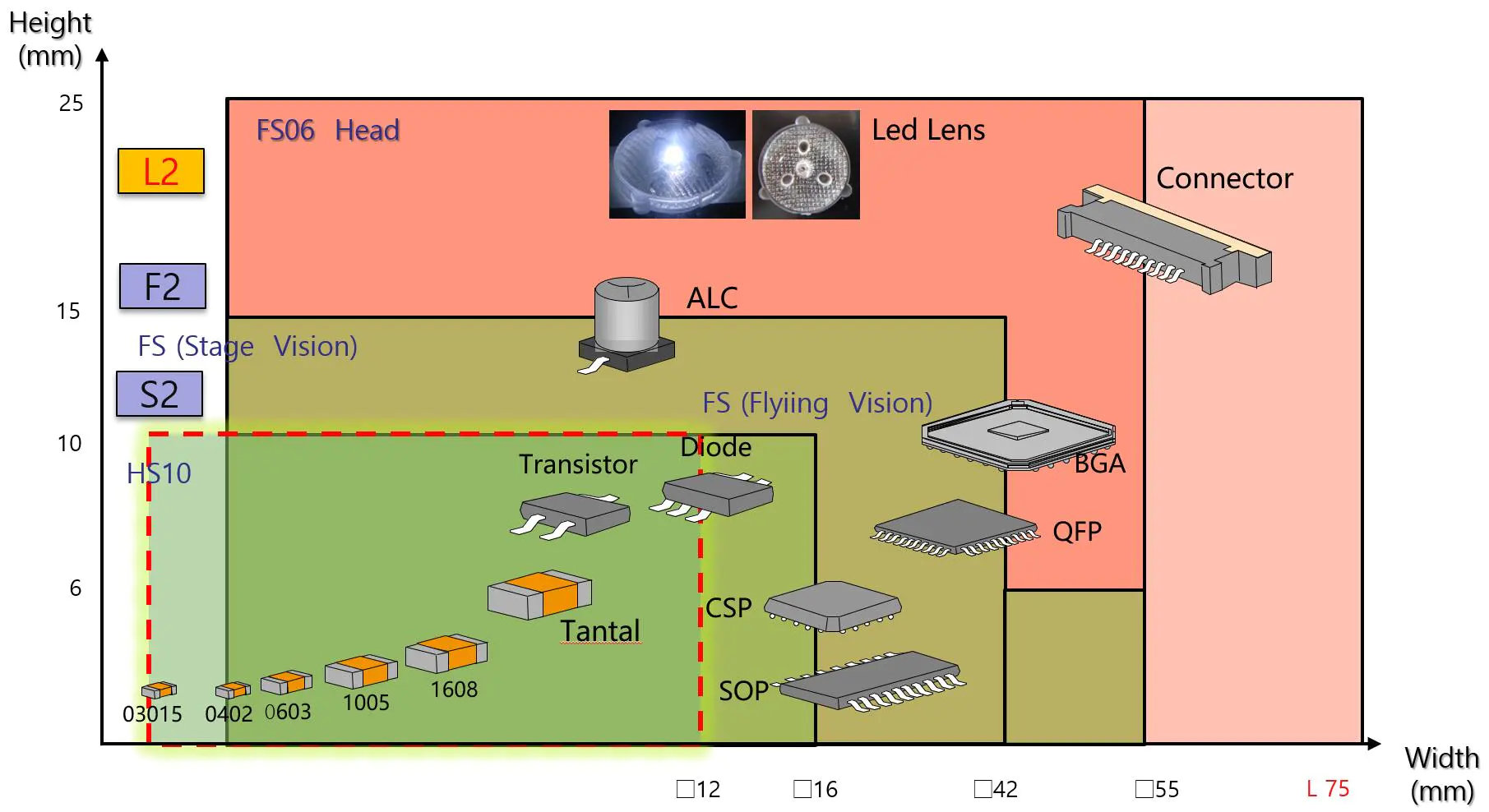

Range of attachable components (as shown)

Hanwha mounter DECAN S2

1 Enhanced ease of equipment software management

2 Optimized software installed in the machine enables simple program creation/editing

3 Large LCD screen provides a variety of work information

4 Highly convenient, high-precision electric feeder

5 Calibration Free & Maintenance Free Electric Feeder

6 Single feeder with Reel Bank structure improves work convenience

7 Automatic alignment of component pick-up positions between feeders increases actual productivity

8 Automated feeder to reduce workload by half (SMART FEEDER)

9 The industry's first automatic feeding and receiving function

The manual feeder preparation and splicing operation has been changed to an automatic method, which significantly reduces the operating time and achieves zero consumption of splicing consumables.

Three, Hanwha mounter DECAN S2 model information:

1 Speed: 92000CPH

2 Accuracy: CHIP 28um(03015),IC 25um

3 Attachable components (mm): Chip 03015 ~5 axes: 12-h10 10 axes: 6-h10

4 Number of axes: 10 x 2 Head

5 Fly Camera FOV:20.5mm

6 PCB size:50 x 40 ~ 510 x 460mm

Max. 740 x 460 mm (1,200 x 460 mm)

7 Feeding station:120ea

8 Machine weight:1,800kg

9 Machine size(mm):1,430(L) x 1,740(D) x 1,485(H)

10 Power supply: 3 phase AC 200/208/220/240/380/415V ±10%.

50/60Hz;Max. 5.0 Kva

DECAN S2

Advanced Chip shooter

1 Speed : 92,000 CPH (Optimum)

2 Structure : 2 Gantry x 10 Spindles/Head

3 Accuracy : ±28μm Cpk≥1.0 (03015 Chip)

±25μm Cpk≥1.0 (IC)

4 Parts Size : 03015~□55mm (H15mm)

5 PCB Size : L510xW460mm (Standard)

L1,200xW460mm (Option)

6 Wide Part Handling Capability

7 Various PCB Transfer Systems

8 Verified Production History Management Solution

9 High Speed Placement

- Categories:Industry News

- Author:Becky Su

- Origin:

- Time of issue:2022-12-02 11:40

- Views:

Hanwha mounter DECAN S2,Hanwha high speed mounter magnetic levitation mounter introduction

Better area capacity than competitor's class equipment, * Optimized high-speed placement of small components

One, Hanwha mounter DECAN S2 advantage:

High Performance

- 2 Gantry, Flying Vision Head

- 92,000 CPH(Optimum, HS10 Head)

High Reliability

- Applicable Linear Motor, high precision, low noise

- Accuracy ±28um@ Cpk≥1.0(03015)

Flexible Production

- Modular Conveyor System

- PCB mountable 740mmx460mm

Easy Operation

- Can be mixed with pneumatic/electric feeders

- Support smart Feeder

Two, Hanwha mounter DECAN S2 features.

Improve the actual production capacity

1 Improve Flying Vision

Enhance LED quality at each Head position to reduce lighting deviation

- Improve the visual recognition difference between Heads

Improve coaxial lighting Contrast

- **Ghost caused by coaxial lighting, improve component recognition rate

2 Improve S/W : Increase placement speed (80,000 CPH->92,000 CPH)

Reduce Cycle time

- Local reference points are assigned according to the number of placements in the relevant Cycle (5ms↓)

Change of Z-Axis Inposition Count (51um->66um)

- Minimize the deviation* of placement height when placing

High precision placement

Achieves Placement Accuracy ±28? (03015)

Improved visual recognition and placement accuracy of 03015 components

- By reducing FOV (24->20.5mm)

Increase the number of Pixel per unit (6.5 -> 7.6)

Improve X-axis position precision (resolution: 3um->2um)

- Change X-Ball screw configuration (Pitch: 30mm -> 20mm)

- Ease load rate Change motor configuration

Improvement of Y-axis position precision(Resolution: 3um ->2um)

- Change of linear motor parameters (3um ->2um)

Provide a wide variety of PCB Flow

Supports Modular Conveyor System that can be changed in the field to produce a wide variety of species

IN/ OUT Conveyor Module can be changed quickly in the field (Shuttle method? Dual method)

Work time required to change modules (mechanical and H/W for example): ~2 hours or less

Range of attachable components (as shown)

Hanwha mounter DECAN S2

1 Enhanced ease of equipment software management

2 Optimized software installed in the machine enables simple program creation/editing

3 Large LCD screen provides a variety of work information

4 Highly convenient, high-precision electric feeder

5 Calibration Free & Maintenance Free Electric Feeder

6 Single feeder with Reel Bank structure improves work convenience

7 Automatic alignment of component pick-up positions between feeders increases actual productivity

8 Automated feeder to reduce workload by half (SMART FEEDER)

9 The industry's first automatic feeding and receiving function

The manual feeder preparation and splicing operation has been changed to an automatic method, which significantly reduces the operating time and achieves zero consumption of splicing consumables.

Three, Hanwha mounter DECAN S2 model information:

1 Speed: 92000CPH

2 Accuracy: CHIP 28um(03015),IC 25um

3 Attachable components (mm): Chip 03015 ~5 axes: 12-h10 10 axes: 6-h10

4 Number of axes: 10 x 2 Head

5 Fly Camera FOV:20.5mm

6 PCB size:50 x 40 ~ 510 x 460mm

Max. 740 x 460 mm (1,200 x 460 mm)

7 Feeding station:120ea

8 Machine weight:1,800kg

9 Machine size(mm):1,430(L) x 1,740(D) x 1,485(H)

10 Power supply: 3 phase AC 200/208/220/240/380/415V ±10%.

50/60Hz;Max. 5.0 Kva

DECAN S2

Advanced Chip shooter

1 Speed : 92,000 CPH (Optimum)

2 Structure : 2 Gantry x 10 Spindles/Head

3 Accuracy : ±28μm Cpk≥1.0 (03015 Chip)

±25μm Cpk≥1.0 (IC)

4 Parts Size : 03015~□55mm (H15mm)

5 PCB Size : L510xW460mm (Standard)

L1,200xW460mm (Option)

6 Wide Part Handling Capability

7 Various PCB Transfer Systems

8 Verified Production History Management Solution

9 High Speed Placement

Four, year-round agent sales Hanwha Samsung brand-new placement machine

Agent of the hot models include:

1,Hanwha (Samsung) new bonder DECAN (high-speed CHIP bonder)

DECAN F2 bonder, DECAN S2 bonder, DECAN L2 bonder.

2,Hanwha (Samsung) brand new bonder SM471plus (high-speed CHIP bonder).

3,Hanwha(Samsung) brand new bonder SM481plus(high speed and high precision bonder);

4,Hanwha(Samsung) brand new bonder SM482plus(multi-functional bonder)

5,Hanwha(Samsung) new bonder EXCEN PRO(high speed module bonder).

Related News

CONTACT US

Hotline:(0086)755-27801389

Mobile: (0086)15323874439

Sale No.1: becky@hysmt.cn

Sale No.2: fhysmt@hysmt.cn

Sale No.3: zksale@hysmt.cn

Sale No.4: sale@hysmt.cn

Sale No.5: elsey@hysmt.cn

GIVE ME A MESSAGE

Copyright: ZK Electronic Technology Co., Ltd 粤ICP备11054297号 Powered by www.300.cn